BL Type Wear-Resistant Rubber Expansion Joint (for concrete, silica sand, slurry, abrasives, pulp)

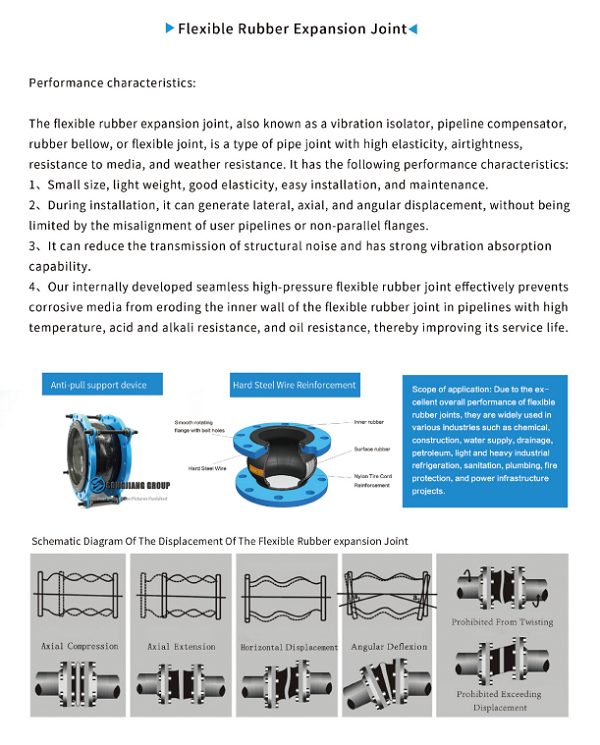

The official website of Shanghai Songjiang Vibration Absorber Co.,Ltd. introduces information about BL Type Wear-Resistant Rubber Expansion Joints (for concrete, silica sand, slurry, abrasives, pulp) in various fields. Songjiang Group provides wear-resistant pipeline expansion joint solutions for the transportation of concrete, silica sand, slurry, abrasives, and pulp. The following are introductions to two solutions.

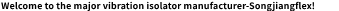

1. Photographic Documentation of BL Type Wear-Resistant Rubber Expansion Joints:

Carbon Steel Flanged Wear-Resistant Rubber Expansion Joint with Wear-Resistant Device (Wear-resistant device can be customized with stainless steel 304/316/321 material).

QT450 Ductile Iron Flanged Wear-Resistant Rubber Expansion Joint with Wear-Resistant Device

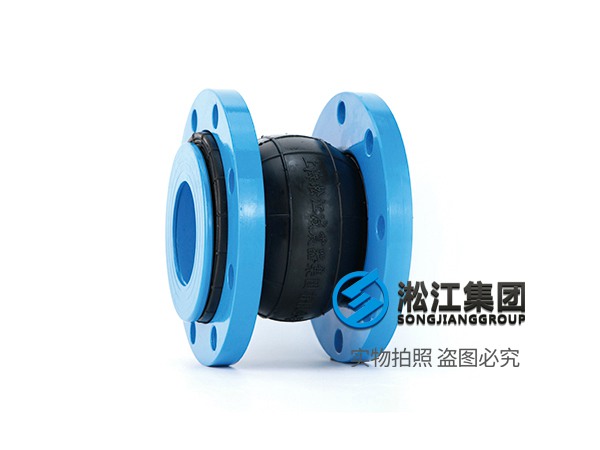

2. Parameters Table for BL Type Wear-Resistant Rubber Expansion Joint:

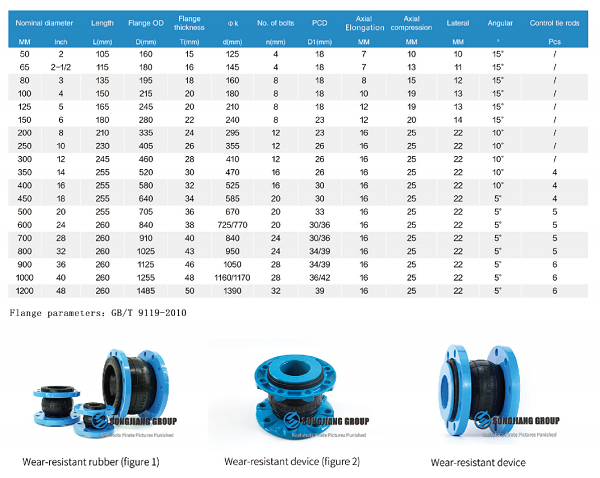

The BL-type wear-resistant rubber flexible joint is primarily employed in pipeline systems requiring wear resistance, such as those handling concrete, silica sand, slurry, abrasives, pulp, and more. It is predominantly produced using a combination of SBR (Styrene Butadiene Rubber) and NR (Natural Rubber), and incorporates Cabot 220 ultra-fine carbon black to achieve high wear resistance (Figure 1). Additionally, it can be complemented by a wear-resistant device, with the option to match the material of the wear-resistant device to that of the main pipeline for optimal wear resistance (Figure 2).

3. Introduction to BL Type Wear-Resistant Rubber Expansion Joints:

4. Introduction to Raw Materials of the Intermediate Rubber Tube in BL Type Wear-Resistant Rubber Expansion Joints:

5.On-site Shipment of BL Type Wear-Resistant Rubber Expansion Joints:

6. Introduction to the Factory of BL Type Wear-Resistant Rubber Expansion Joints:

Related Links: Metallurgical Rubber Joint Case