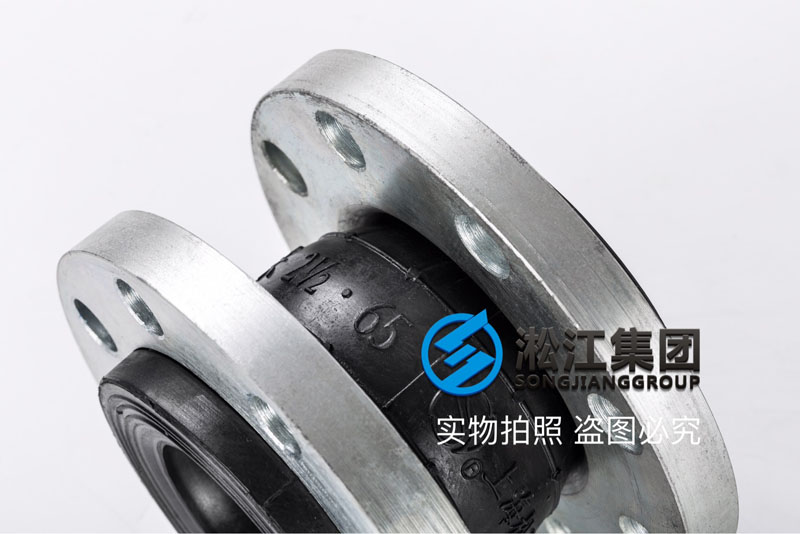

2.DN65 Galvanized Flanged Rubber Expansion Joint Introduction:

Name: Single Sphere Galvanized Flanged Rubber Expansion Joint

Model: KXT-DX

Diameter: DN65

Pressure: PN10, PN16, PN25

Length: 110mm

Extension: 6mm

Compression: 12mm

Lateral Movement: 10mm

Angular Movement: 15°

Flange Material: Carbon Steel Forged (Galvanized Treatment)

Rubber Material: Natural Rubber

Operating Temperature: -10°C to 80°C

Flange Standard: GB/T9119-2000

3.DN65 Galvanized Flanged Rubber Expansion Joint Performance Features:

Small volume, light weight, good elasticity, easy installation and maintenance.

During installation, it can generate lateral, axial, and angular displacement without being restricted by pipeline misalignment or non-parallel flanges.

It can reduce structural transmission noise and has strong vibration absorption capability during operation.

It has high pressure resistance, good elasticity, large displacement, can balance pipeline deviation, absorb vibration, and effectively reduce noise. It is easy to install and can significantly reduce pipeline system vibration and noise. It can fundamentally solve various problems such as interface displacement, axial expansion, and eccentricity of pipelines. The rubber material used is polar rubber, with good sealing performance, light weight, easy installation and maintenance, and long service life. However, it should avoid contact with sharp metal instruments to prevent piercing the rubber body.

Relevant certificates: Certificate of Conformity, Warranty Certificate, Inspection Report from Shanghai Quality and Technical Supervision Bureau, Performance Test Report from National Type Test Center, ISO9001-2005 Certificate, Material Certification, User Manual, etc.

Manufacturer: Shanghai Songjiang Shock Absorber Group Co., Ltd.

4.Why Choose Shanghai Songjiang Group?

Songjiang Group is a domestic rubber expansion joint industry with its own new type of automated production plant and its own quality control system. Let’s take a look at how we control the production process of rubber expansion joints step by step:

Purchase specified brand raw materials – Chemical testing before each batch of raw materials is put into storage – Making test pieces for testing – Automatic batching of rubber formulas – Automatic feeding – Automatic mixing – Automatic open mixing – Automatic cutting – Automatic forming – Automatic curing – Visual robot curing defect detection – Hydraulic testing – Performance testing – Fatigue testing – Intelligent warehouse – Packaging – Shipping.

This series of quality control processes, along with automated production equipment, allow mechanized control of product quality, reduce human errors to zero, and ensure that every rubber joint leaving the factory is qualified. Our rubber joints have passed the national type test and obtained the National Type Test Certificate. In the field of rubber joints, we are the best.

5.DN65 Galvanized Flanged Rubber Expansion Joint Factory Introduction: