【NR】DN100 Single Sphere Rubber Joint: ‘Cooling Circulation Pump for Hydropower Station Units

The official website of Shanghai Songjiang Vibration Absorber Co.,Ltd.presents to you information about the 【NR】DN100 Single Sphere Rubber Expansion Joint: ‘Cooling Circulation Pump for Hydropower Station Units.’ Songjiang Group provides DN100 Single Sphere Rubber Expansion Joints for the cooling circulation pumps in the cooling systems of numerous hydroelectric power station generator units, serving the purpose of shock absorption and noise reduction.

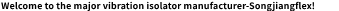

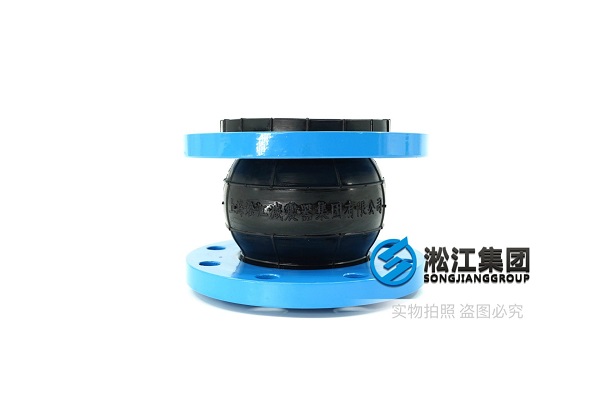

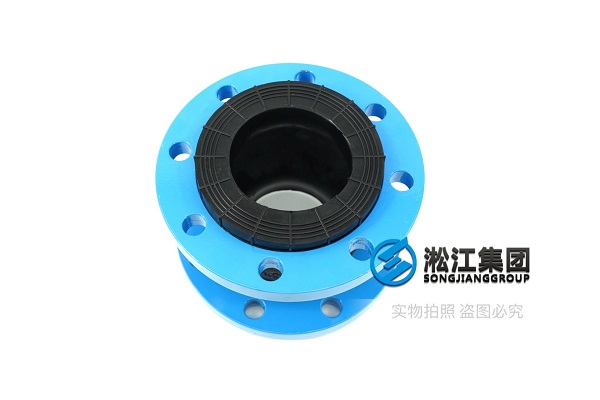

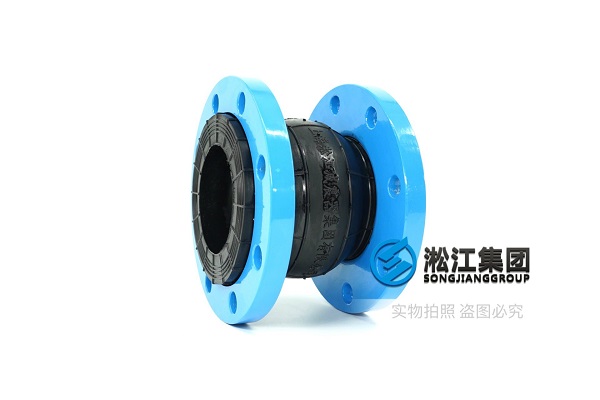

1. Physical Photos of DN100 Rubber Expansion Joints for Cooling Circulation Pumps in Hydropower Station Units:

2. Introduction to Rubber Expansion Joints for Cooling Circulation Pumps in Hydropower Station Units:

5. Introduction to Cooling Circulation Pumps in Hydropower Station Units:

Hydropower stations, composed of hydraulic systems, mechanical systems, and electric power generation devices, are hydraulic hub projects that achieve the conversion of water energy to electrical energy. The sustainability of electricity production demands the continuous utilization of water energy in hydropower stations. Through the construction of the reservoir system in hydropower stations, the distribution of hydraulic resources in time and space is artificially regulated and altered, realizing the sustainable utilization of hydraulic resources. To effectively convert the potential energy in the reservoir into electrical energy, hydropower stations require a hydro-mechanical-electric system, consisting mainly of pressure conduits, turbines, generators, and tailrace pipes.

The hydro-mechanical-electric system achieves the conversion of water energy to mechanical energy through the coordination of pressure conduits and turbines. The linkage between turbines and generators ultimately achieves the goal of using water energy for electricity production. The efficiency of the conversion from water energy to electrical energy is closely related to the force at the mouth of the pressure conduit, which is influenced by factors such as reservoir water volume, reservoir water level, and the inclination angle of the pressure conduit. Therefore, the process of electricity production in hydropower stations involves coordinating the operation between the reservoir and the hydro-mechanical-electric system, as well as the various parts within the system. The hydropower station system is essentially a hydro-mechanical-electric coupling system.

Hydraulic generators are also called ‘hydraulic turbine generators.’ Each turbine and its matching generator in a hydropower station form a power generation unit, the primary power equipment for electricity production in hydropower stations. When the water flow drawn from rivers, lakes, etc., with potential energy at a higher elevation passes through the turbine, it converts the water energy into mechanical energy that drives the turbine, and the generator then converts the mechanical energy into electrical energy for output.

The role of the hydraulic generator set is to transfer water with potential energy from higher locations, such as rivers and lakes, to lower locations. As the water flows through the turbine, it is converted into mechanical energy, and the turbine drives the generator to generate electricity, converting mechanical energy into electrical energy.

The hydroelectric generator is driven by the hydraulic turbine. The rotation speed of the generator determines the frequency of the output alternating current, so maintaining the stable speed of the rotor is crucial for ensuring a stable frequency. Closed-loop control can be employed to control the speed of the hydraulic turbine, using the frequency signal sample of the generated alternating current as feedback to the control system that adjusts the opening angle of the turbine guide vanes, thereby controlling the output power of the hydraulic turbine and stabilizing the generator speed.

Hydraulic generator sets are energy conversion devices that transform the potential energy of water into electrical energy, typically composed of turbines, generators, governors, excitation systems, cooling systems, and power station control equipment.

6. Introduction to the Factory of Rubber Expansion Joints for Cooling Circulation Pumps in Hydropower Station Units:

Related links:Hydroelectric Power Plant Rubber Joint Cases