【NR】DN150 single sphere rubber expansion joint for plate heat exchanger unit with 3-year lifespan

The official website of Shanghai Songjiang Vibration Absorber Co.,Ltd.introduces to you: 【NR】DN150 single sphere rubber expansion joint “3-year maintenance-free for plate heat exchanger units.” Songjiang Group provides rubber joints for numerous high-pressure plate heat exchanger units, and our factory guarantees 3 years of maintenance-free operation. Any maintenance issues within the 3-year period are covered by the manufacturer’s warranty.

1. Physical photograph of DN150 plate heat exchanger unit rubber expansion joint:

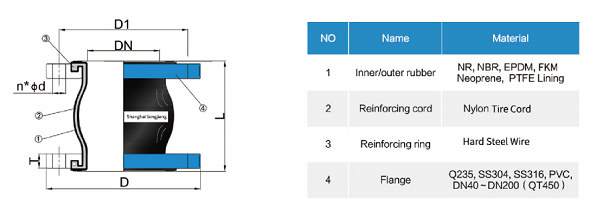

2. Introduction of rubber expansion joints for plate heat exchanger units:

5. Introduction to Plate Heat Exchanger Units:

Plate heat exchanger units, as a type of heat exchanger unit, are characterized by the use of plate heat exchangers. Under the same pressure loss conditions, their heat transfer coefficient is 3-5 times higher than that of tube heat exchangers, occupying one-third of the area of tube heat exchangers. The thermal recovery rate can reach over 90%.

Steam or hot water, controlled by a temperature control valve, is sent into the plate heat exchanger unit according to the required flow rate of the heating system. The heat exchanger indirectly heats the return water from heating (air conditioning) users. The heated water first passes through a stainless steel core filter, then enters the heat exchanger through a circulating pump, and is heated before being supplied to users. This process repeats continuously. The primary heat transfer medium returns to the primary heating pipe network after heat exchange in the plate heat exchanger unit. The system’s water loss is automatically replenished by a makeup water pump at a set pressure to ensure stable system pressure and normal operation.

The heat exchanger unit consists of a plate heat exchanger, intelligent temperature control device, intelligent electrical control device, circulating pump, rubber joint, makeup water pump, pressure-regulating expansion tank, makeup (condensation) tank, filter, valves, instruments, sensors, piping base, and more.

This heat exchanger unit has advantages such as high efficiency, energy conservation, intelligence, and automation. It can be widely applied in civil buildings such as factories, offices, schools, residential communities, villas, as well as commercial buildings like shopping malls, hotels, restaurants, resorts, for heating, air conditioning, domestic hot water supply, life water supply, and winter water supply for swimming pools. It can also be used for preparing industrial process water and in various places requiring heat exchange.

Advantages of Plate Heat Exchanger Units:

Automatic timed start and stop of plate heat exchanger units. It can achieve timed start and stop control based on time, date, and different periods.

Backup circulating pump and heat exchanger automatically switch at scheduled times. The circulating pump switches at scheduled times, and in case of a circulating pump failure, it automatically bypasses. The main plate heat exchanger and backup plate heat exchanger switch at scheduled times to maximize the system’s lifespan.

Automatic switching between power frequency and variable frequency. The system collects temperature and pressure signals to control the variable frequency of circulating pumps and makeup water pumps. It can automatically switch between variable frequency and power frequency for multiple circulating pumps and makeup water pumps.

Compared to intelligent heat exchanger units, plate heat exchanger units have a simpler, more intuitive, and user-friendly human-machine interface. Equipped with a touch screen, this system has a user-friendly interface, displaying complete system operation status, equipment status, and various thermal parameters. Operating parameters are centrally displayed. It can be controlled locally or networked with the central control room for convenient remote monitoring by users.

Powerful remote communication capabilities of plate heat exchanger units. They can be wired or wirelessly connected to the host computer. They can achieve local area network control and wireless monitoring. When a fault occurs, a wireless alarm signal is immediately sent to the administrator’s mobile phone for prompt system maintenance.

6. Introduction to the Rubber Expansion Joint Factory for Plate Heat Exchanger Units:

Related links:Shopping Mall Rubber Joint Case