【NG】K16S-32 Rubber Vibration Absorber “Pressure Filter Machine”

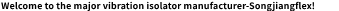

Shanghai Songjiang Shock Absorber Group Co., Ltd. official website presents: 【NG】K16S-32 Rubber Shock Absorber information, model SDKSS32, manufacturer model SJNG. Songjiang Group provides K16S-32 rubber shock absorbers for many automotive engine production factories’ pressure filter machines. Here is a detailed introduction.

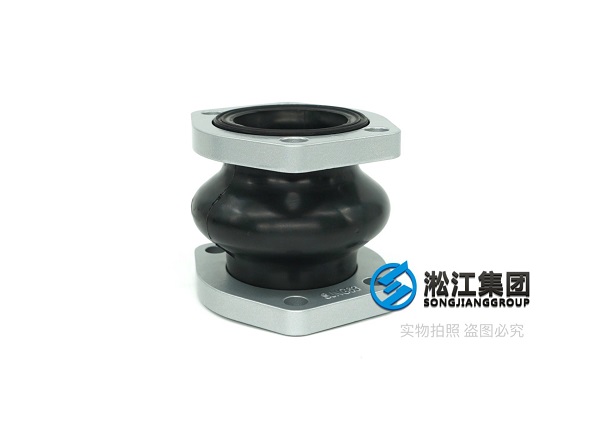

1. Photograph of the physical K16S-32 Rubber Vibration Absorber for pressure filters:

3.Introduction to Pressure Filter Machine:

A pressure filter machine is a mechanical device used for solid-liquid separation, employing a special filtering medium and applying pressure to facilitate the percolation of liquids. It has been widely utilized since the early 18th century in chemical production and continues to find applications in various industries such as chemical, pharmaceutical, metallurgical, dyeing, food processing, brewing, ceramics, and environmental protection.

Key features of pressure filter machines include stability, ease of operation, safety, and labor-saving. The metal press barrel is manufactured from seamless steel pipes, and the plastic steel filter plate is precision-cast, ensuring high temperature and pressure resistance for durable performance.

Hydraulic Compression:The hydraulic compression mechanism consists of a hydraulic station, oil cylinder, piston, piston rod, and hydraulic connection between the piston rod and the compression plate. The hydraulic station comprises an electric motor, oil pump, relief valve (pressure adjustment), directional valve, pressure gauge, oil circuit, and oil tank.

During hydraulic compression, the hydraulic station supplies high-pressure oil to fill the chamber formed by the oil cylinder and piston. When the pressure exceeds the frictional resistance of the compression plate, the compression plate slowly presses against the filter plate. Once the compression force reaches the pressure value set by the relief valve (indicated by the pressure gauge), the filter plate or filter frame (for plate and frame type) is compressed, and the relief valve starts unloading. At this point, the motor power is cut off, indicating the completion of the compression process.

During retraction, the directional valve switches, allowing hydraulic oil to enter the rodless chamber of the cylinder. Once the hydraulic pressure can overcome the frictional resistance of the compression plate, the compression plate starts to retract.

For automatic pressure maintenance, the compression force is controlled by an electrical contact pressure gauge. The upper and lower limit pointers of the pressure gauge are set to the desired values. When the compression force reaches the upper limit of the pressure gauge, the power supply is cut off, and the oil pump stops supplying oil. As potential internal and external leaks in the oil circuit system may cause a decrease in compression force, when it drops to the lower limit pointer of the pressure gauge, the power supply is resumed, and the oil pump starts supplying oil again. This cycle ensures the maintenance of compression force throughout the filtration process.

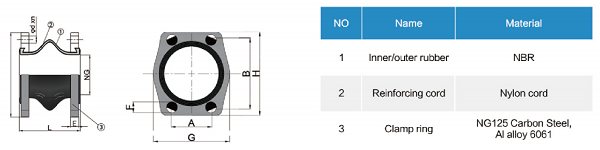

4.K16S-32 pressure filter machine rubber vibration damping throat delivery site:

5. Introduction to the factory of K16S-32 pressure filter machine rubber vibration damping throat: