【NG】K16S-40 Rubber Joint “Extruder Machine”

Shanghai Songjiang Vibration Absorber Co.,Ltd. official website presents: 【NG】K16S-40 Rubber Joint “SDKSS40 Extruder Machine” information. The NG type rubber joint product is designed for the hydraulic pump system return oil pipeline of imported extruder machines. Here is the introduction of the K16S-40 rubber joint.

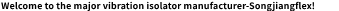

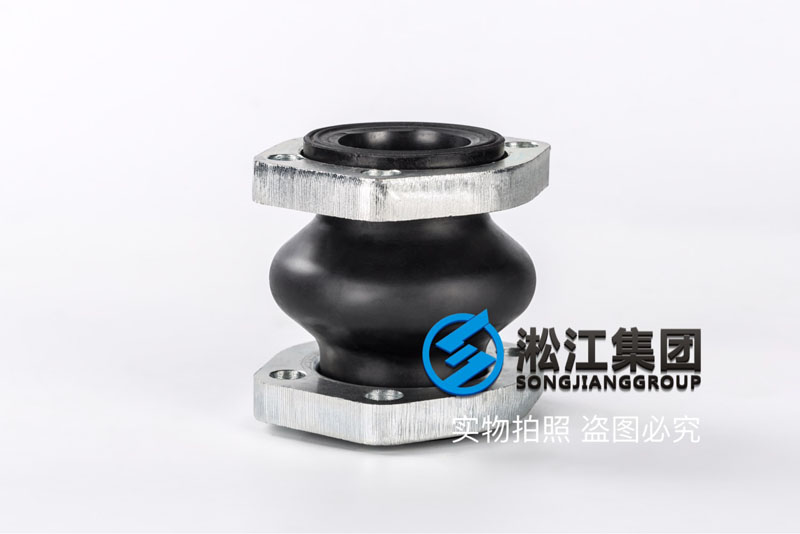

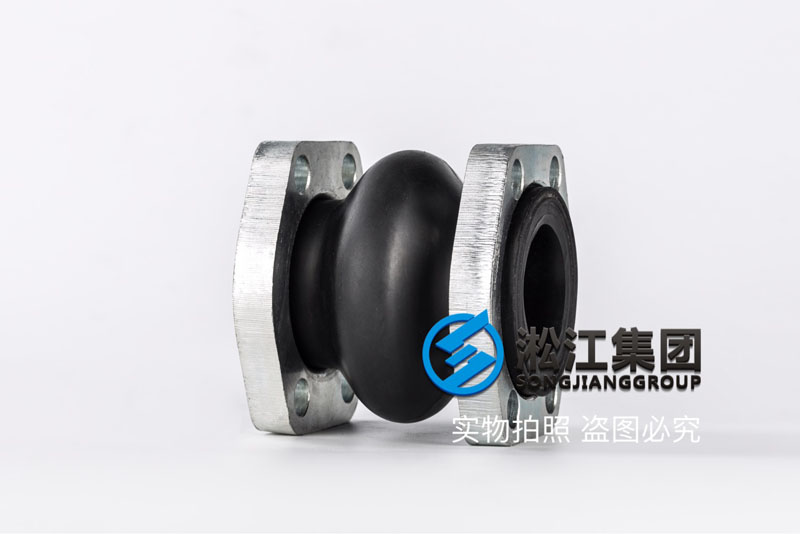

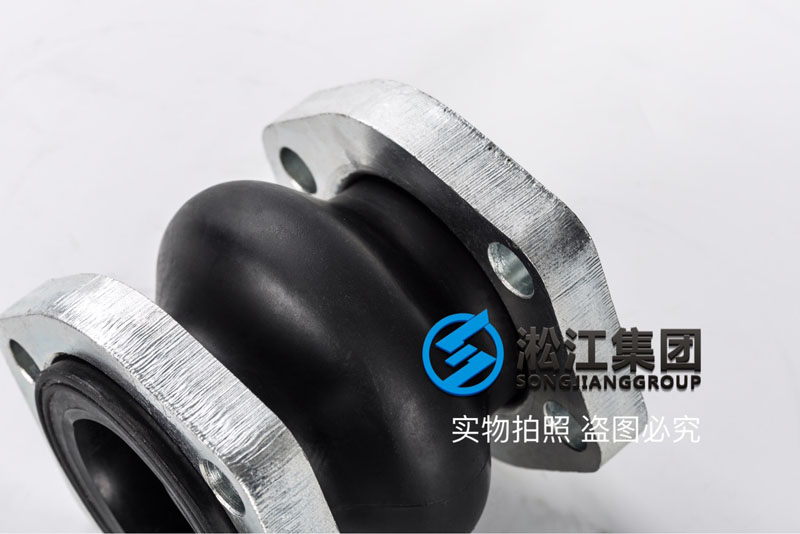

1. K16S-40 Extruder Machine Rubber Joint Physical Photography:

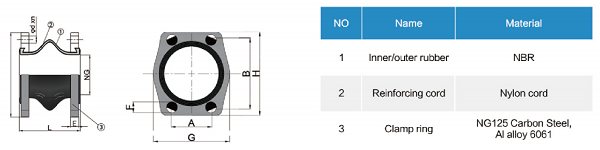

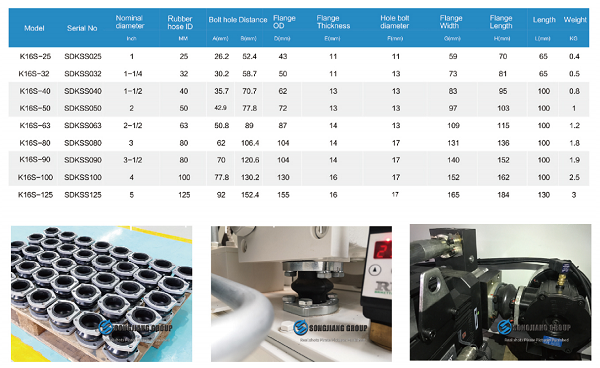

2.Technical Parameters of K16S-40 Extruder Machine Rubber Joint:

Rubber Material: Nitrile Rubber

Flange Material: Aluminum Alloy (NG125 is carbon steel) with spray coating treatment.

Installation Position: Hydraulic system of excavators, shield machines, and extrusion machines.

Function: Acts to dampen vibration and reduce noise.

Quality Assurance: 12 months.

Delivery Time: Available in stock.

3. Introduction to Extrusion Machine:

The extrusion machine is the main equipment for producing light alloy (aluminum alloy, copper alloy, and magnesium alloy) pipes, rods, and profiles. Its emergence and development have undergone tremendous changes in just over a century. From manual hydraulic presses with several meganewtons of force, it has evolved into fully automatic hydraulic presses with two hundred meganewtons of force. The types of extrusion machines have also greatly increased. The capacity and quantity of extrusion machines reflect the production technology level of an enterprise. The capacity, quantity, production capacity, and equipment level of extrusion machines in a country reflect the industrial development level of that country.

The extrusion machine mainly consists of three parts: mechanical part, hydraulic part, and electrical part.

The mechanical part consists of a base, prestressed frame tension column, front crossbeam, movable crossbeam, X-type guided extrusion cylinder seat, extrusion shaft, supply spindle mechanism, residual separation shear, sliding die seat, etc.

The hydraulic system mainly consists of the main cylinder, side cylinder, locking cylinder, perforating cylinder, large-capacity axial piston variable pump, electro-hydraulic servo valve (or electro-hydraulic proportional control valve), position sensor, oil pipe, oil tank, and various hydraulic switches.

The electrical part mainly consists of a power distribution cabinet, operating platform, PLC programmable controller, upper industrial control machine, and display screen.

Metal extrusion machines are the main equipment for metal extrusion processing. Metal extrusion processing is an important method of using metal plastic deformation. Its important feature is to process metal ingots into pipes, rods, and profiles in one go, almost instantaneously, with hardly any other method comparable to it. The backbone materials used in various fields such as the decoration materials of beautiful and elegant buildings; airplanes flying across continents and oceans; spacecraft and space stations exploring outer space for humanity; railway, subway, light rail, maglev train vehicles, ships, and speedboats are closely related to extrusion processing.

4. Introduction to the Factory of K16S-40 Extrusion Machine Rubber Joint:

Related Links:Rubber Joint New Energy Cases